Consolidated Operational KPI Library For Mining Performance

Consolidates-operational-kpi-library-for-mining-performance … Read More

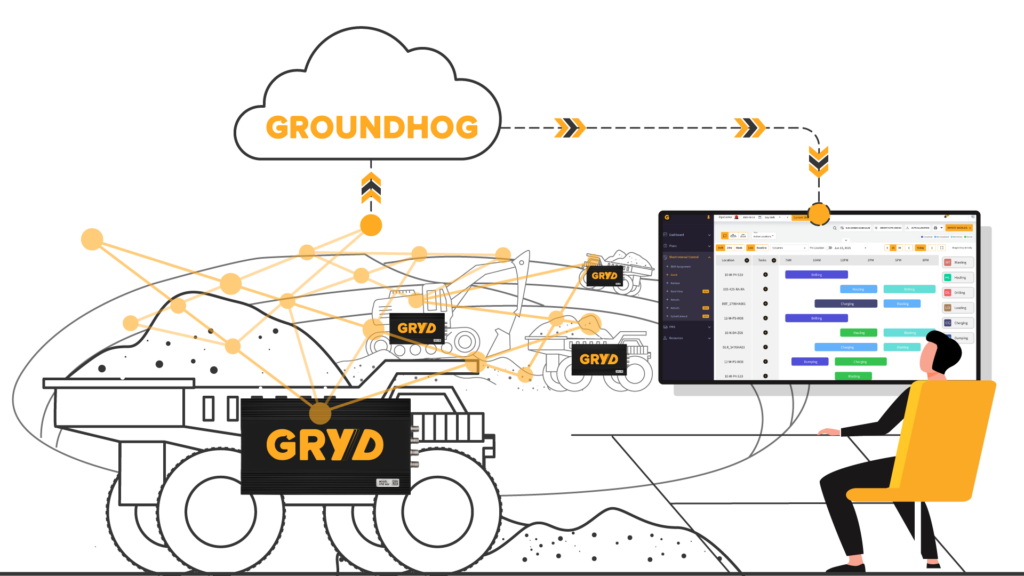

GroundHog GRYD enables reliable, real-time equipment communication and data transfer — building a secure, high-performance network that powers smarter mining operations.

Create Reliable Networks for Open-Pit Operations Using GroundHog GRYD

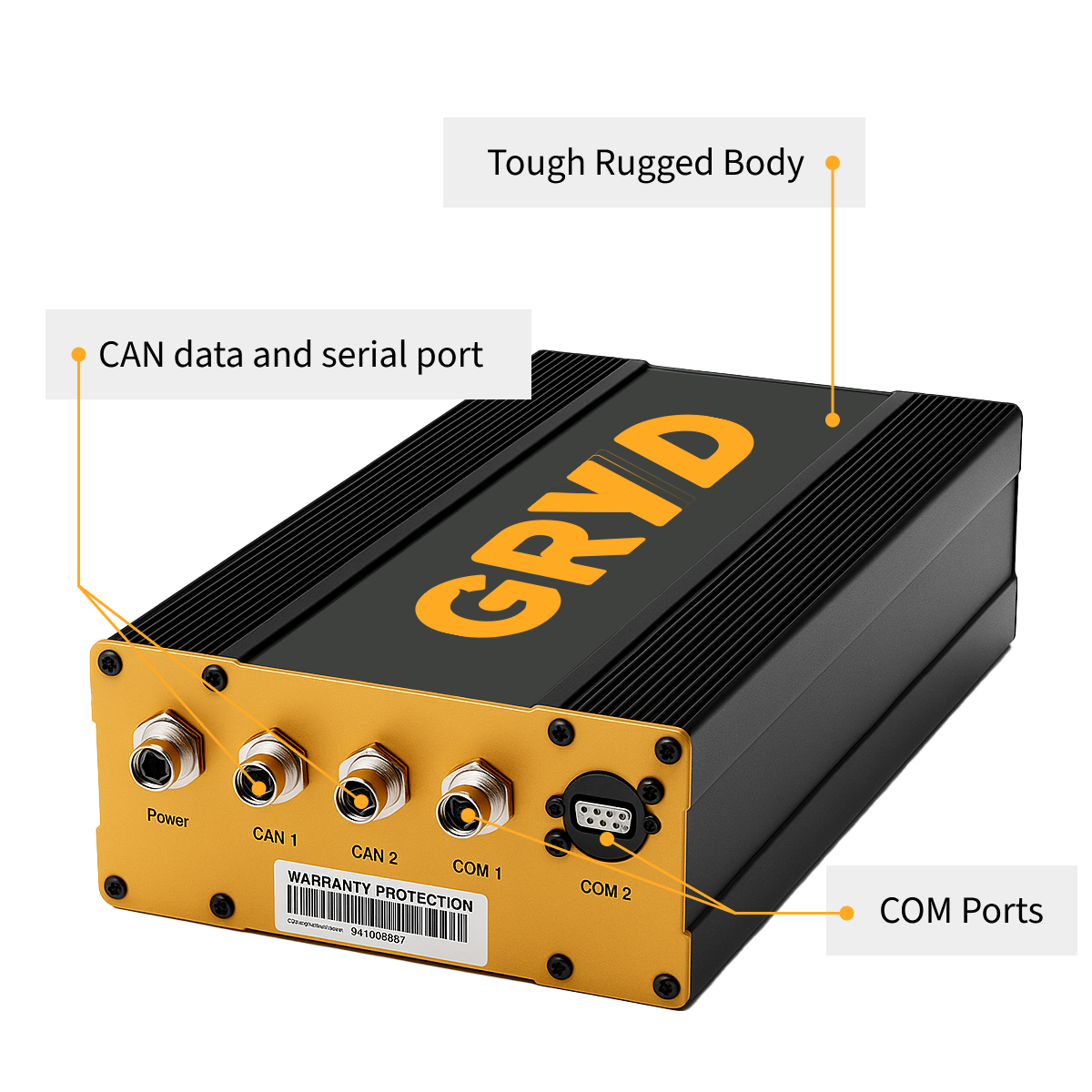

Traditional open-pit operations depend on external, fragmented hardware and Wi-Fi solutions to connect tablets and equipment. GroundHog GRYD provides a unified hardware box that combines routing, CAN data extraction, and serial connectivity — ensuring smooth, low-latency communication across your fleet.

Get Real-Time Machine Data Without Third-Party Hardware

Before GRYD, GroundHog relied on third-party devices for machine data. GRYD now provides a direct interface between GroundHog tablets and mining equipment — reading data from onboard systems using CAN or serial connections. This allows operators to view accurate, real-time trip and performance data.

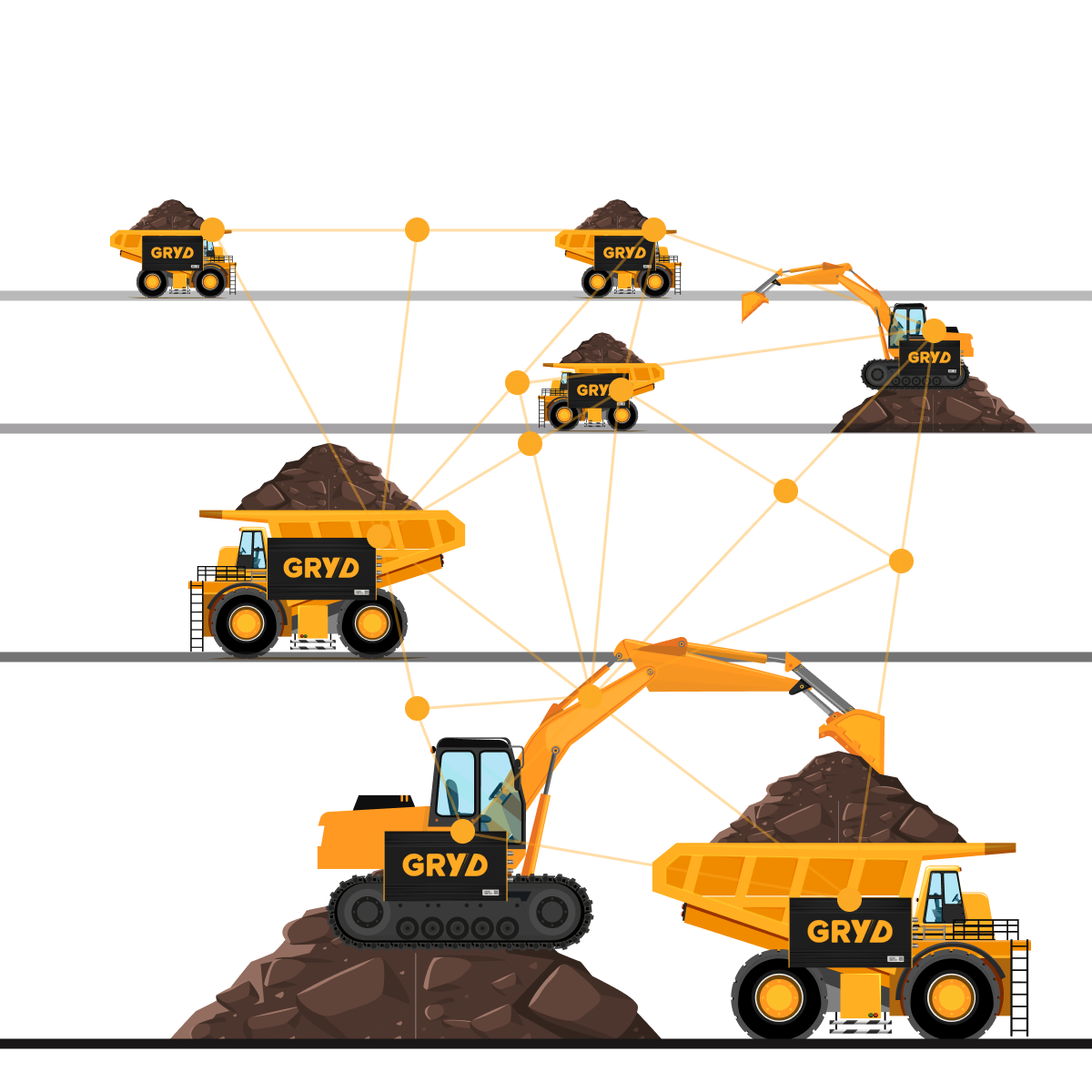

Enable Peer-to-Peer Communication Across Your Fleet

GRYD’s advanced router architecture lets diggers, trucks, and auxiliary machines communicate directly — even in areas with weak or intermittent Wi-Fi coverage. Each GRYD unit can form a local mesh network, allowing critical data to move seamlessly across your fleet.

Automate Data Flow Between Equipment and GroundHog Applications

GRYD automates the collection of essential machine and performance data — from trip counts to load metrics — reducing manual entry and ensuring faster, more reliable reporting for dispatch and operations teams.

Engineered for Reliability

Developed and manufactured in-house, GRYD is GroundHog’s first proprietary hardware solution — built to withstand the rigors of open-pit mining. With its ruggedized design and multi-device support, GRYD ensures uninterrupted operation and scalable connectivity across your site.

GRYD turns every heading, stope and drawpoint into a self-optimising micro-network that feeds live equipment and tonnage data straight to mine control—no surveyors, no radios, no waiting.

Read related blogs and access useful links

Consolidates-operational-kpi-library-for-mining-performance … Read More

Long-term mine plans don’t fail because of one bad assumption.

This technical guide brings together the Digital and Technology KPIs

GroundHog GRYD is an integrated hardware solution designed for open-pit mining operations. It combines routing, CAN data extraction, and serial connectivity in one rugged device — enabling real-time communication between mining equipment, tablets, and GroundHog applications.

GRYD establishes a local, reliable network across the pit by linking diggers, trucks, and auxiliary machines through peer-to-peer mesh connections. Even when Wi-Fi is weak or unavailable, GRYD maintains continuous data flow between machines and the GroundHog platform.

Yes. GRYD connects directly to a machine’s onboard systems using CAN or serial interfaces. It eliminates the need for third-party devices, providing a seamless flow of real-time trip, load, and performance data to operators and dispatchers.

GRYD reads operational data such as load counts, haul cycle information, and equipment performance metrics. It integrates with high-precision GPS, VMI sensors, and weigh-scale systems to deliver accurate, real-time insights to GroundHog FMS.

Absolutely. GRYD automates equipment data collection and synchronization with GroundHog applications. This reduces human error, improves reporting accuracy, and allows shift supervisors to access real-time productivity and utilization data without manual updates.

Each GRYD unit can communicate directly with nearby machines, forming a local mesh network. This allows trucks and shovels to share data even when the main site network or Wi-Fi connection drops, ensuring uninterrupted fleet coordination.

Unlike traditional setups that rely on multiple external routers and third-party devices, GRYD consolidates all networking and data interface functions into a single, unified unit. This reduces latency, simplifies setup, and improves reliability in challenging mining environments.

Yes. GRYD was developed and manufactured in-house by GroundHog engineers, specifically for the harsh conditions of open-pit operations. Its ruggedized housing, stable connectivity, and expandable architecture make it ideal for high-demand mining applications.

GRYD’s modular, expandable design allows easy integration with future GroundHog systems and third-party tools. As mines evolve toward greater automation and digitization, GRYD provides a foundation for scalable, future-ready connectivity.

Reliable in-pit connectivity for all equipment.

Real-time data visibility for operators and supervisors.

Reduced downtime from network disruptions.

Automated data capture and faster shift reporting.

Rugged, purpose-built design for open-pit mining.